Why Every DFW Homeowner Needs a Strategic Maintenance Approach

A preventative maintenance plan is your roadmap to avoiding costly breakdowns and keeping your home systems running smoothly year-round. Instead of waiting for your HVAC system to fail on the hottest day of summer, a preventative approach schedules regular check-ups and services before problems occur.

Quick Answer: Essential Components of a Preventative Maintenance Plan

- Asset Inventory – List all equipment needing maintenance (HVAC units, appliances, etc.)

- Maintenance Schedule – Set regular service intervals based on manufacturer recommendations

- Standardized Checklists – Create consistent procedures for each maintenance task

- Performance Tracking – Monitor system efficiency and identify trends

- Clear Responsibilities – Assign who does what and when

- Documentation – Keep detailed records of all maintenance activities

- Continuous Improvement – Regularly review and adjust your plan based on results

Think about it this way: you wouldn’t drive your car 50,000 miles without an oil change, yet many homeowners neglect their HVAC systems until they completely break down. Research shows that preventive maintenance can reduce downtime by up to 80% and maintenance costs by up to 40%.

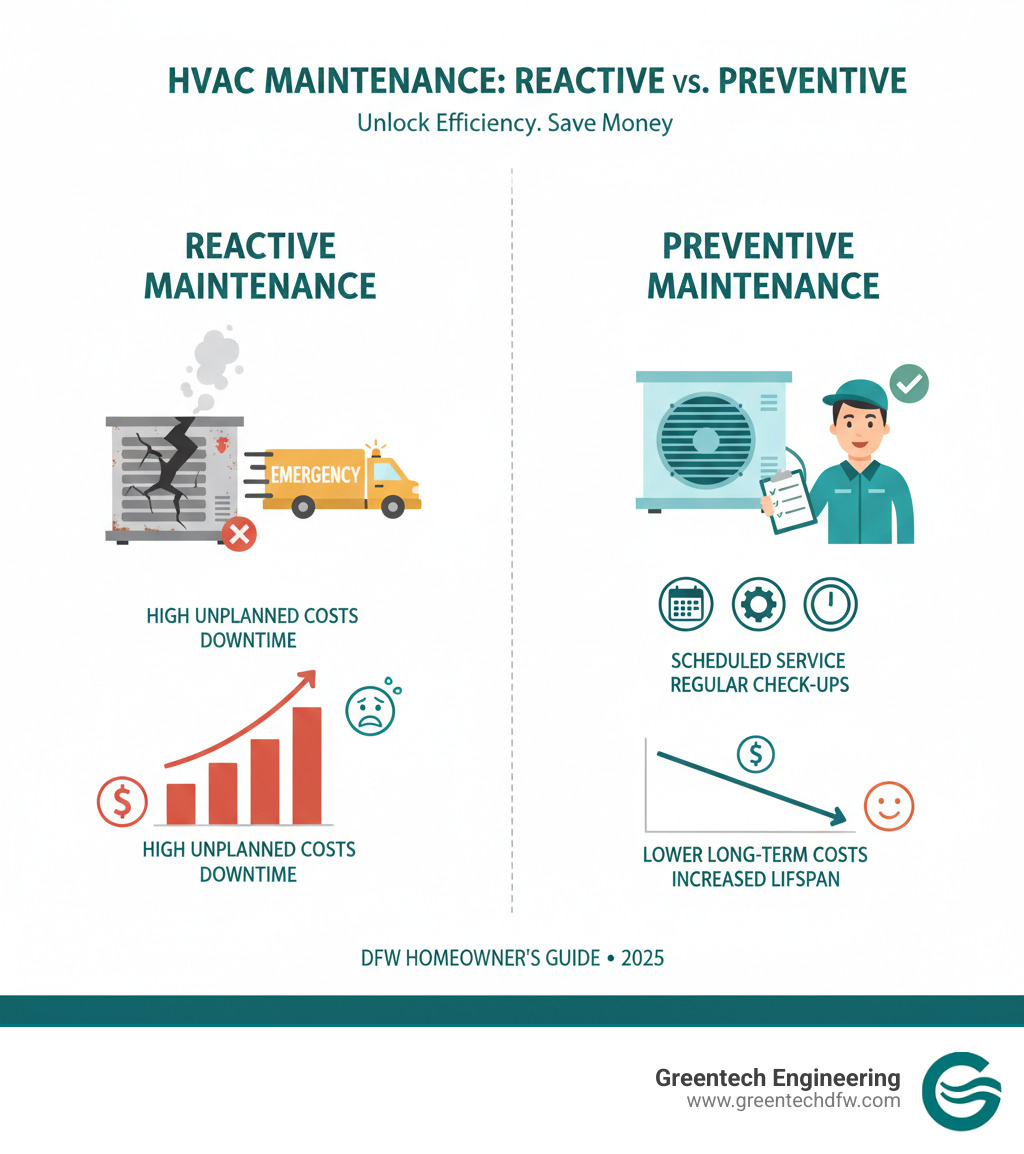

The difference between reactive and preventive maintenance is like the difference between emergency room visits and regular doctor check-ups. One costs more, causes stress, and often comes at the worst possible time. The other keeps you healthy and catches problems early.

This guide walks you through 8 proven steps to create a winning preventative maintenance plan that will save you money, reduce stress, and keep your home comfortable all year long.

What is a Preventive Maintenance Plan and Why Does it Matter?

Think of a preventative maintenance plan as your home’s health insurance policy. It’s a structured approach to keeping equipment like your HVAC system running smoothly through scheduled inspections, cleaning, and minor repairs. Instead of waiting for a breakdown and scrambling for emergency service, this proactive method takes control.

Without regular care, your home’s systems are like ticking time bombs. A clogged filter or a loose wire can lead to a complete system failure on the hottest day of the year—a common scenario in the DFW area. Preventive maintenance flips the script. Instead of reacting to problems, you prevent them. Instead of paying for costly emergency repairs, you invest in scheduled service that costs a fraction of a major failure.

The difference between the two approaches is stark:

| Feature | Reactive Maintenance (Run-to-Failure) | Preventive Maintenance |

|---|---|---|

| Cost | High (emergency repairs, premium for rush service, collateral damage) | Lower (scheduled, predictable, avoids major failures) |

| Downtime | Unplanned, often lengthy, significant disruption | Planned, minimal, scheduled during convenient times |

| Safety | Higher risk of accidents or hazards due to sudden failures | Improved safety due to regular inspections and upkeep |

| Asset Life | Shorter lifespan, increased wear and tear | Extended lifespan, optimal performance over time |

| Predictability | Low (always a surprise) | High (scheduled, budgetable) |

The benefits are significant. Studies show proactive maintenance can reduce equipment downtime by up to 80% and lower maintenance costs by up to 40%. Your equipment also lasts longer, with some estimates showing a 20% extension in lifespan. This means your HVAC system, water heater, and other appliances will serve you faithfully for years longer.

Beyond the numbers, you gain peace of mind with fewer surprises and improved safety. Regular inspections can catch potential hazards like gas leaks or electrical issues before they become dangerous, aligning with safety principles used by organizations like OSHA. A well-maintained system is a safer system. To learn more about how this applies to your cooling system, see the Benefits of Regular AC Maintenance.

The 8 Essential Steps to Build Your Winning Preventative Maintenance Plan

Ready to transform your home from a ticking time bomb of potential breakdowns into a well-oiled machine? Building a solid preventative maintenance plan doesn’t have to feel overwhelming. Think of it like organizing your closet – a little upfront effort saves you from frantically searching for that one shirt when you’re already running late.

We’re about to walk you through eight proven steps that will take you from the chaos of “wait until it breaks” to the calm control of “we’ve got this covered.” These aren’t theoretical concepts – they’re practical, field-tested strategies that we use with our DFW clients every day. Let’s build something that will serve you for years to come.

Step 1: Establish Goals and Prioritize Your Assets

Before scheduling tasks, define what you want to achieve with your preventative maintenance plan. Common goals include reducing downtime, lowering costs, and improving safety. Writing these down provides a clear purpose for your plan.

Next, create a comprehensive asset inventory and prioritize your equipment. A main HVAC unit failing in July is more critical than a guest bathroom fan. Use a criticality assessment to determine which systems need attention first. Ask yourself: how disruptive and costly would a failure be? Your high-priority equipment—like your main heating and cooling system, water heater, and refrigerator—should be the focus of your maintenance schedule. A free Asset Criticality Assessment Template can simplify this process.

Step 2: Define and Track Key Performance Indicators (KPIs)

You can’t manage what you don’t measure, which is why tracking Key Performance Indicators (KPIs) is crucial for your preventative maintenance plan. These metrics show if your plan is working.

- Mean Time Between Failures (MTBF): This tracks how long equipment runs between breakdowns. A rising MTBF indicates your plan is effective. You can learn more about the technical details of MTBF.

- Mean Time To Repair (MTTR): This measures how quickly you can restore service after a failure. A lower MTTR means less disruption.

- Planned Maintenance Percentage (PMP): This shows the ratio of scheduled work to emergency repairs. A high PMP means you’re successfully shifting from reactive to proactive care.

Use these maintenance metrics to make data-driven decisions that improve your results.

Step 3: Create an Inventory of Your Equipment and Assets

To build a robust preventative maintenance plan, you need a detailed asset inventory. Assumptions can be dangerous, so get organized.

Start with major systems like your HVAC units, furnaces, and heat pumps. Then, list water heaters and major appliances. For each item, record:

- Model and serial numbers

- Installation date

- Maintenance history

- Specific location (e.g., “attic unit above master bedroom”)

This information is vital for ordering parts, filing warranty claims, and getting technical support. If you’re unsure about your HVAC setup, our guide to Understanding Your Central Split System can help.

Step 4: Develop Detailed Maintenance Checklists

Standardized procedures in the form of checklists ensure consistent, thorough maintenance and turn good intentions into reliable results.

A solid HVAC checklist should cover key tasks like lubrication of moving parts, filter changes for air quality, and cleaning coils for efficiency. It should also include inspecting electrical connections and checking refrigerant levels, as these small steps prevent major headaches. A checklist is useful for both DIY tasks and professional service calls, ensuring nothing is missed and providing a clear record of work performed. For more guidance, you can find helpful Checklists online. Also, familiarize yourself with the Signs an HVAC System Needs Repair to spot issues early.

Step 5: Create a Preventative Maintenance Plan Schedule with Accurate Triggers

Proper timing is key for maintenance. The goal is to find the sweet spot between over-servicing and risking a breakdown by using accurate triggers to schedule tasks.

- Manufacturer recommendations are the best starting point.

- Usage data tells you how hard your equipment is actually working. An HVAC in a DFW summer needs more attention than one in a milder climate.

- Historical failures from your maintenance records help you anticipate future issues and schedule service proactively.

Use time-based triggers for seasonal tasks (e.g., spring/fall HVAC tune-ups) and usage-based triggers for others (e.g., changing air filters based on runtime). For more scheduling strategies, check out this resource on Preventive Maintenance Schedule | Maintenance Care.

Step 6: Get Buy-In and Implement the Plan

A plan is only effective if it’s followed. This step focuses on turning your strategy into action. For homeowners, get your family on board by explaining the benefits, like avoiding surprise breakdowns and repair bills.

Assign clear responsibilities: who schedules professional service, who handles monthly filter changes, and who keeps the outdoor unit clear of debris? Involving everyone helps ensure commitment. Consider a pilot program by focusing on one system, like your HVAC, to work out any kinks. A gradual rollout prevents overwhelm and allows you to refine your process. The important thing is to start and improve as you go. See how professionals approach this by reviewing the Process Technicians Follow for HVAC Services.

Step 7: Leverage Technology for Execution

Modern technology can automate and streamline your preventative maintenance plan. While a Computerized Maintenance Management System (CMMS) is common in industry, homeowners can use smartphone apps to apply the same principles.

Key features to look for include:

- Work order automation to schedule service reminders.

- Asset tracking to keep equipment info and history in one place.

- Data centralization to have your maintenance history at your fingertips.

- Mobile access to update records and check schedules from anywhere.

The Internet of Things (IoT) offers even smarter solutions. Smart sensors and thermostats provide real-time monitoring and can alert you to potential issues before they become major problems. This technology supports good maintenance practices, making them easier and more reliable.

Step 8: Analyze, Adjust, and Continuously Improve

The best preventative maintenance plan is never finished; it’s a cycle of continuous improvement that keeps your program effective.

Regularly monitor KPIs. If you’re not meeting goals like reducing emergency repairs, your plan needs adjustment. Review maintenance data to find patterns and opportunities for improvement. When a failure occurs, use Root Cause Analysis (RCA) to understand why and prevent a recurrence. This free RCA template can help.

Gather feedback from everyone involved, fine-tune schedules based on what you learn, and optimize checklists as you find better methods. Your plan should evolve with your experience and your equipment’s needs. For local expertise in refining your strategy, explore our HVAC Maintenance Plan Carrollton TX to see how professional support can help.

Beyond the Basics: Types of Maintenance and Crucial Industries

Once you master the basics, you can tailor your preventative maintenance plan using different strategies for different equipment. Not every asset requires the same approach.

Understanding the Different Types of Preventive Maintenance

Your plan can incorporate several approaches:

-

Time-Based Maintenance: This is the most common type, where tasks are performed on a fixed schedule. For example, your HVAC system gets a tune-up every spring, and you change air filters every 90 days. It’s simple and predictable.

-

Usage-Based Maintenance: This approach triggers tasks based on actual operation. For instance, you might change a filter after 500 hours of runtime instead of a fixed time period. This is ideal for equipment with variable use.

-

Condition-Based Maintenance: This advanced method uses monitoring to determine when service is needed. A smart thermostat might alert you to a drop in efficiency, signaling it’s time for a check-up, rather than waiting for a scheduled date.

-

Predictive & Prescriptive Maintenance: These cutting-edge strategies use data analysis to forecast failures and recommend solutions. While common in industrial settings, smart home technology is making these concepts more accessible to homeowners.

Why This Approach is Trusted by Critical Industries

It’s no surprise that a preventative maintenance plan is non-negotiable in industries like manufacturing, aviation, and healthcare. In these fields, equipment failure can lead to massive financial loss or even safety crises. They rely on proactive maintenance to ensure reliability and safety, following standards from organizations like the Food and Drug Administration. The same principles that keep a factory running or a hospital safe can be applied to keep your home comfortable and secure.

Frequently Asked Questions about Preventive Maintenance

What is the difference between preventive and predictive maintenance?

Preventive maintenance is scheduled based on time or usage, like a regular doctor’s checkup. For example, servicing your HVAC system every six months. It’s a proactive approach to stop problems before they start.

Predictive maintenance uses real-time data from sensors to predict when a failure might occur. It’s like a fitness tracker for your equipment, alerting you to issues based on the asset’s actual condition. For most homeowners, a solid preventative maintenance plan offers the best balance of protection and simplicity.

What are the biggest challenges when implementing a PM plan?

The most common problems are:

- Getting buy-in: It can be hard to convince family members to spend money on equipment that is currently working.

- Initial investment: Setting up a plan requires an upfront commitment of time and sometimes money for professional services.

- Lack of information: Many homeowners don’t have easy access to equipment details like model numbers or installation dates.

- Breaking old habits: Shifting from a reactive “fix it when it breaks” mindset to a proactive, scheduled one requires discipline.

Once past these initial challenges, the peace of mind and long-term savings make the effort worthwhile.

How do you measure the ROI of a preventive maintenance program?

The return on investment (ROI) of your preventative maintenance plan is clear when you track the savings:

- Reduced emergency repairs: Compare your spending on unexpected breakdowns before and after implementing the plan. The drop is often dramatic.

- Extended equipment lifespan: Delaying a multi-thousand-dollar HVAC replacement by several years is a massive financial win.

- Lower utility bills: A well-maintained system runs more efficiently, which directly translates to lower monthly energy costs.

- Avoided collateral damage: Preventing a catastrophic failure also prevents secondary costs like water damage or other property issues.

By tracking these metrics, you’ll see that a PM plan is not an expense but a smart investment in your home.

Conclusion

Starting on a preventative maintenance plan is one of the smartest strategic investments you can make in your home’s future. Think about it – you’re essentially giving your most critical systems the gift of longevity, peak efficiency, and unwavering reliability. We’ve walked through how shifting from that nail-biting “fix it when it breaks” approach to a thoughtful, proactive strategy can dramatically reduce downtime by up to 80%, slash maintenance costs by up to 40%, and extend your equipment’s lifespan by 20%. That’s not just impressive – it’s life-changing for your comfort and your wallet.

The eight essential steps we’ve outlined aren’t just theoretical concepts – they’re your roadmap from chaos to complete control. Establishing clear goals and prioritizing your assets gives you direction. Creating detailed inventories and standardized checklists ensures nothing falls through the cracks. Developing smart schedules and getting everyone on board turns your plan from paper into practice. Leveraging technology streamlines everything, while continuous improvement keeps your plan sharp and effective.

What makes this approach so powerful is that it puts you in the driver’s seat. Instead of being surprised by a broken furnace in January or a failed AC unit during a scorching DFW summer, you’re anticipating needs and staying ahead of problems. It’s about achieving that wonderful peace of mind that comes from knowing your home’s systems are running smoothly, efficiently, and safely.

Your home deserves this level of care, and you deserve the comfort and confidence that comes with it. A well-executed preventative maintenance plan isn’t just maintenance – it’s your insurance policy against unexpected breakdowns and your ticket to increased reliability year after year.

For expert help in maintaining your home’s most critical systems, like your HVAC, trust the straightforward, engineering-focused approach of Greentech Engineering. We’re here to help DFW homeowners open up efficiency and achieve lasting comfort. Contact us to learn more about our heat pump services in Carrollton, TX and how we can tailor a preventative maintenance plan that works perfectly for your home’s unique needs.